Our Supply Chain

Arlington Automotive champions a different type of supply chain; we consolidate it to make it both shorter and stronger – and the benefits get passed on to you.

Our skillset is all under one roof!

So, work with us and you can expect a more cost-effective proposition. Not just greater efficiency, but higher levels of quality, and greater continuity of supply. With one point of contact you’ll see reduced admin and delivery time. With fewer links in the supply chain, you’ll see benefits to the environment, too.

Design

Pressing

Welding

Coatings

Assembly

Logistics

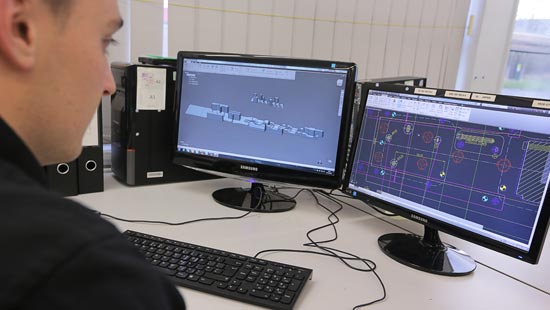

Design

For assembly, manufacturing feasibility and fitness for purpose, our design engineers work closely with OEMs in developing their products. Using project management capabilities, our team can deliver continuous improvements and lean manufacturing, provide full sample approval processes and timing plans, and offer savings through improved productivity.

Pressing

We have a wide range of both manual and progressive presses

From 80T through to 600T capacity, and in a variety of bed sizes. An extensive investment program concluded in 2015 with a new press hall and new presses being installed, totalling over £2.5M.

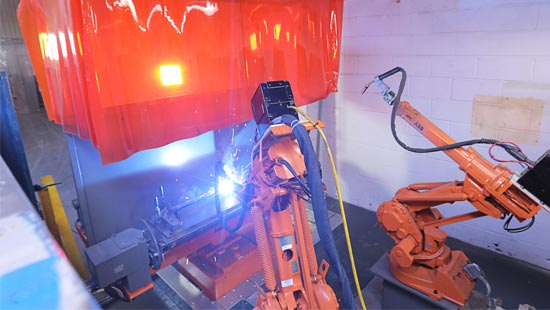

Welding

Our MiG and spot welding capabilities include both manual and automated: six single and double MiG Robot cells with fully automated manipulation, up to seven axis; 15 pedestal spot welding machines with full weld monitoring, complemented by three special-purpose spot welding machines for more complex assemblies.

Coatings

We have two fully automated facilities on site, Electrophoretic Deposition (ED) and Powder Coating. The ED line provides Zinc Phosphate pre-treatment and online stoving, to achieve 1000 hours salt spray resistance. The Powder Coating line offers Oxylan pre-treatment and online stoving to achieve 480 hours salt spray resistance. We also provide other surface coatings such as wet spray, anodising and zinc plating.

Assembly

Working with our customers, we engineer, develop and assemble Original Equipment to ensure a first-time fit for initial production runs and aftermarket requirements. Assembling pipes for a range of automotive uses – including fuel lines, vacuum brakes, engine breathers, tank venting, air suspension harnesses and switchable engine mounts – we guarantee a simple fit for high-complex projects.

Logistics

Our experience in logistics is critical to our ability to deliver high-quality assemblies at a competitive price. With over 580 suppliers and growing, we use a fully integrated system with full stock management procedures in place. Our strengths include: products supplied direct to line side, packaging management, a vendor rating system established to monitor and develop suppliers, multi-currencies, ethical trading and sequencing capabilities.